In steel making as well, this type of material which is used quite often are the HR coils. HR the letters stand for Hot-rolled "This refers to the fact that these coils are heated and then formed into a certain form. We will go into detail about the advantages of using HR coils to make steel.

An added benefit of HR coils is that it simplifies the work for everybody who works in manufacturing. As HR coils are in semi-finished items, for this will not be changed as much or comparable to the workers. That way, they can not only give more time to other important tasks but also use multiple tools in parallel instead of one by one. This will cut down time as well as cost of the company. Moreover, the final product quality can be enhanced through HR coils used. Better and stronger steel are produced when better workability of materials.

This will help factories too a lot to work faster than they used to be with the HR coils. These coils, because they are these forms and shapes already can be slotted right into the process of manufacturing and then mold under heat. What that means is factories can make many more products, much faster. On the other hand, a greater output streamlines how well factory operations occur. Faster production translates to faster service delivery, a highly-desirable offer in the fast-paced world today.

Both cars and buildings are made up of HR coils, which is very vital in their manufacturing process. They are typically employed in automotive manufacturing to craft robust pieces, which are necessary for both safety and operation (e.g. car frames, engine compounds). As a car ages, some of these parts need to be able to withstand general wear and tear. The construction industry also uses HR coils for the production of high-rigidity steel beams, as well as other structural elements. Consequently, they are incredibly robust and possess excellent strength for a pair of work gloves responsible in some vital jobs where safety is the focus.

HR coils are something you should really consider if youre in the manufacturing industry. But they should be able to help make you work better, smarter and develop good products people use. Given the benefits of HR coils, it seems only logical to go for them in manufacturing. Isn't it time you started using HR coils in your factory? Using HR coils correctlyWhen you have the right suppliers and adequate processes in place, you can tap into all that HR coils have to provide.

Our products come with BV, ISO, SGS, CE and various other certifications. We supervise the entire process of production quality and ensure it is controlled, and can provide hr coils results, however, we also permit testing by other third parties. Assistance to clients in getting the highest quality steel products.

hr coils offer clinet a 24 24/7 online support after sales. If there's issues with the product, such as for example, the packaging or design and appearance, we'll help to fix them.

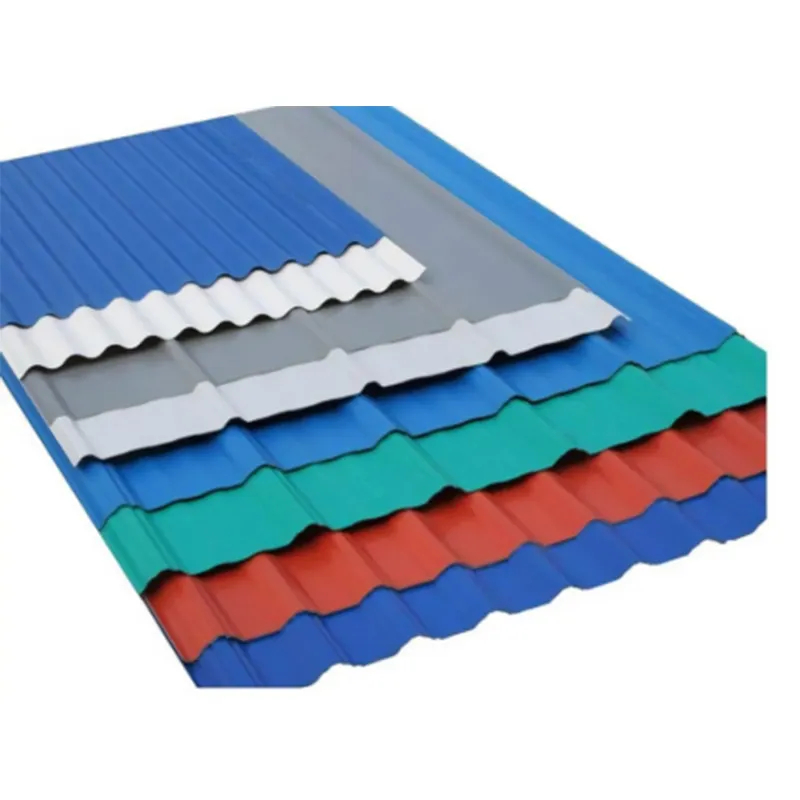

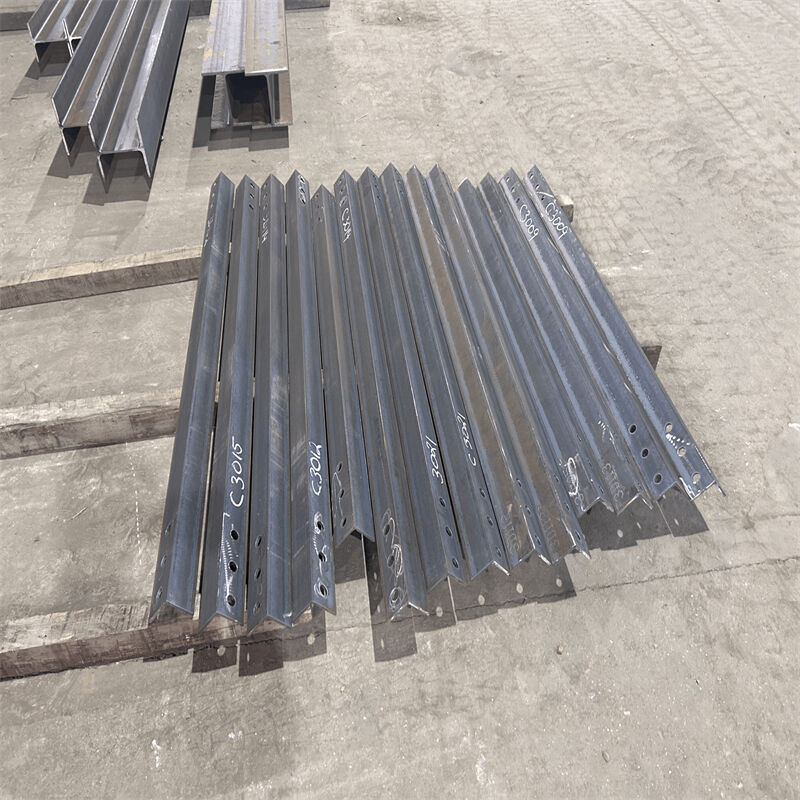

hr coils have formed a cooperation with more than 200 steel producers at home and abroad, can supply carbon and alloy steel stainless steel plate tubes, coil, various types of profiles, and hardware accessories, committed to providing customers with the most suitable solutions to meet individual customer specifications.

We have extensive expertise in transport across borders providing services and products to more than 80 countries. Our logistics team is reliable and we provide sea, air and land transport. The goal is to guarantee the quickest and most secure hr coils.