You know when you just glance at a piece of metal roofing, or that big wall made out of it? I have, but that most likely was made out of rolled sheet metal! Roll Forming is a unique technique of changing flat metal sheets into various desired shapes, specifically curves or angles. This is a very useful process for creating and constructing most sort of stuffs which we use on our daily basis. -

Sheet metal is rolled into curves using a machine tool known as a rollformer. Rollformers use rollers to bend and shape the metal as it passes through each roller system. These rollers are retractable or replaceable in different configurations, which creates oblique and curve formations. So the same machine can produce a variety of shapes! The types of materials that are used and a lot of skill and experience is required for the metal to come out perfect.

But how is rollforming possible? To start, a flat sheet of metal is threaded through the rollformer. Once the metal sheet is placed inside, these rollers activate to start bending that piece of metal into whatever shape we ordered. Other times a tool called cut-off is used and then once the piece has taken form it is cut per specific given lengths.

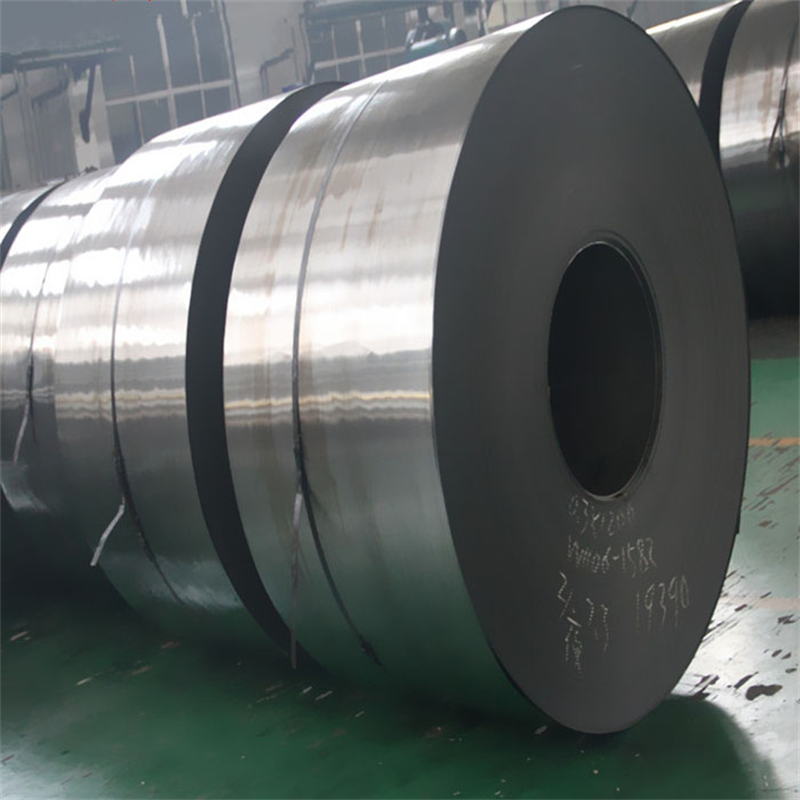

Rolled sheet metal has a variety of uses and benefits that it provides to the people who use it. One major reason is because it's tensile and durable. As such, it is capable of withstanding severe weather conditions including heavy rainfall and extreme snow. Also, it is lightweight as well so that makes easier to transport and install (doing a bit of time-saving atop).

Untrimmed, welded sheet might serve the same purpose. It used for roofs and walls in building construction. Of course, that is not all it can be used for! In addition, rolled sheet metal is used in items like gutters and pipes - that's right, your truck even has some parts made out of the stuff! This makes it one of the most versatile materials in industries.

What Can Be Made From Rollformed Sheet Metal A typical product is metal roofing. We call it metal roof and is a type of roofing that uses sheets, usually rolls in to differently shaped types such as R-Panel or Standing Seam. Commonly associated with longevity and strength, metal roofs are also energy-efficient - which can mean savings on heating/cooling costs.

Metal framing is also a popular item. It is a construction framing type where metal pieces are rollformed into specific shapes and sizes. Metal FramingOften used in larger buildings like schools and offices, metal studs are known for their strength while also being easy to install. It's fast to set up and nearly bulletproof, which is why builders love it.

As we've provided products and services to more than 80 countries and regions, our cross-border transportation is a rich experience and has a trustworthy logistics team. Sea and air transport, land transportation can meet, the purpose is to be the rolled sheet metal and most secure speed to get the products to you.

Clinet offers a 24- hour online rolled sheet metal support. If there are any problems regarding the product, for example, the appearance or packaging or appearance, we'll be the first to address these issues.

We have developed a strong connection with more than 200 steel rolled sheet metal across the world and in the United States. We offer carbon steel, alloyed steel, stainless steel coil, tubes, all kinds of profiles and accessories.

Our products are BV, rolled sheet metal SGS CE certified. We supervise the entire process of production quality, control it strictly and provide tests, however, we also allow testing from third parties. Provide assistance to customers in finding top-quality steel products.