Due to how the steel is manufactured, cold rolled steel sheets are an important manufacturing process in many industries. It is a core material for making many, which are fabricated by combined an accurate process and called "cold rolling. While processing the piece of steel is carefully rolled elongated and thinner through several roll stands. The steel, meanwhile, is cooled efficiently to further its durability.

Lastly, a perfect smooth and flat surface with cold rolled steel sheets includes the features that makes car parts produced easy wiht this type of work. Besides, these sheets have an as uniform thickness which is most necessary in the production of building materials.

The Major Benefits of Using Cold Rolled Steel Sheets in Construction Industry

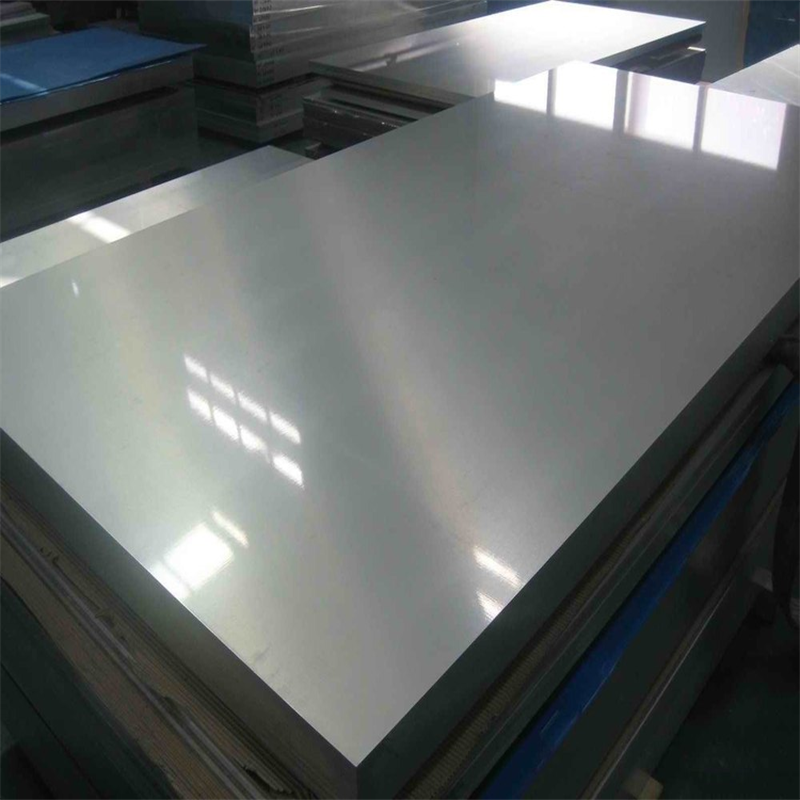

Because cold-rolled steel sheets are some of the strongest available, they are used for a number of construction projects. These sheets can be very useful when weight compression is heavy and some sort of building process involving steel frames need strong bond. Also, this rust resistant nature of them has to play a vital role in enhancing the life-span oh structures.

Although cold rolled steel sheets provide several advantages, here are a few things to keep in mind. Brittleness: These sheets can become brittle, causing them to crack or break under too much bending. The high performance and advanced properties allow for stronger, more durable joints to be created that are difficult or impossible in other materials only because the resistance of this material is different from any others.

These cold rolled steel sheets find a place in industries of all typifications, from the automotive trades to computing programming. These sheets are vital in every step of the way from manufacturing appliances such as refrigerators and washing machines to being a go-to for construction application like roofing and siding. Further, it is an important sector that contributes to the creation of crucial parts in car manufacture.

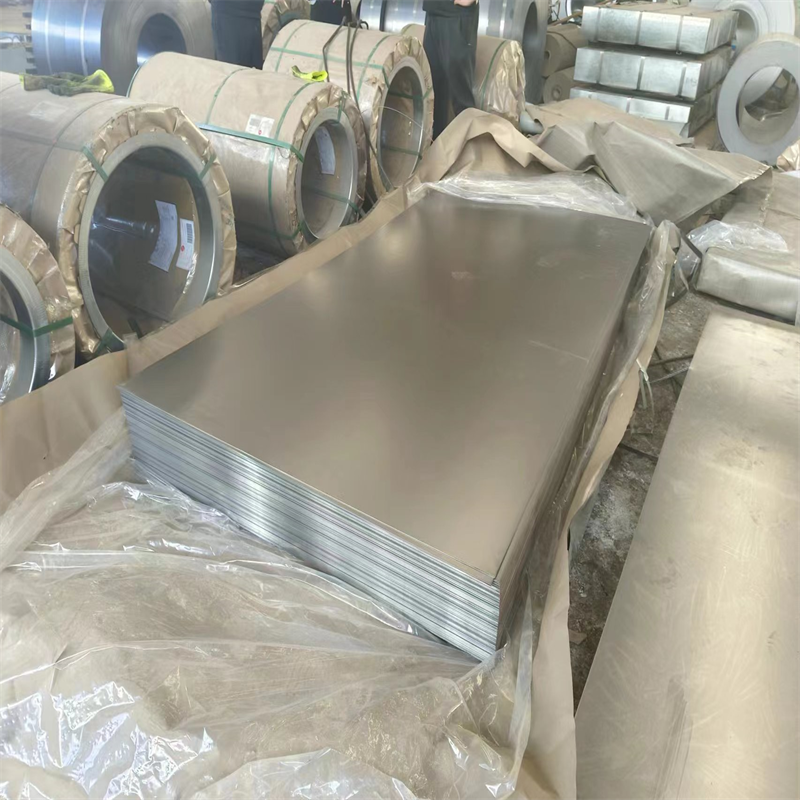

Key Steps to Take If Considering Cold Rolled Steel Sheets For Projects 1 You Need Materials Sourcing a reliable supplier is the first thing you should do to get your necessary materials. Furthermore, the proper tools and equipment are essential to work with this material properly. After that, you will just have to take the necessary care in getting acquainted with how cold rolled steel sheets are handled and operated.

We have cold rolled steel sheet of experiences in international transport providing services and goods to more than 80 countries. Our logistics team is reliable and we offer sea, air and land transport. The aim is to ensure the most efficient and safest delivery.

cold rolled steel sheet products come with SGS, BV CE and other certificates. We track every aspect of production quality, ensure that it is strictly controlled and provide testing results, however, we also allow testing from third parties. Provide assistance to customers in finding high-quality steel products.

We cold rolled steel sheet developed a strong partnership with more than 200 steel suppliers both in the US and overseas. We are able to supply carbon steel, alloyed steel, stainless steel coil, tubes, all kinds of profiles, and hardware accessories.

Clinet offers a 24- day online after-sales assistance. If there are any cold rolled steel sheet regarding the product, for instance, packaging or the appearance We'll be the first to resolve them.