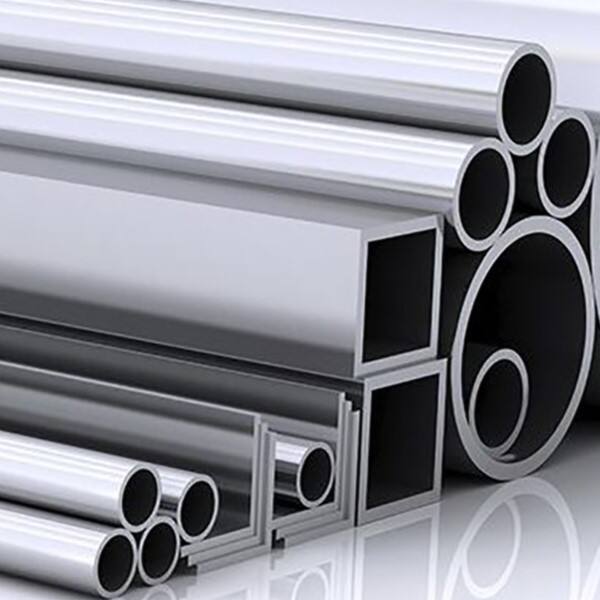

Steel pipes are a great distribution of different forms and dimensions. For example: Long and round or like a straw. This is what we call a pipe! Stainless Steel Pipes are simply pipes made out of a very strong metal called stainless steel, which is alike the iron pipe. These pipes can be used in a variety of projects which vary immensely, from buildings to factories or even our homes.

They are quite similar to regular steel pipes, but the fact that they can be produced from an enhanced and improved metal type- stainless steel makes them extremely resistant to rust. The presence of rust is a big issue because it can cause steel pipes to weaken, leading them to eventually break. In contrast, stainless steel pipes could remain rust-free for many years. That is why it is used in construction, as well as different industries. It is used all over the world, and many people still trust stainless steel pipes as they have seen how well these things hold up.

There are two ways to produce stainless steel pipes, one is welded and the other is seamless. For example, in the case of welded pipes one heats steel up and then connects two pieces together with a welder.') This process produces a great bond, but also leaves a seam where the two sections come together. In contrast, seamless pipes are made by heating the steel until it flows out and forms a thick liquid. It is then molded into a pipe that has no joints, or seams. This generally makes seamless pipes stronger than all but the strongest welded pipe forms. Because of this, they are used for a multitude of purposes.

Stainless pipes have many advantages and are therefore well-suited for use in construction as an industrial material. These are hella strong, and will not flex or break under heavy loads. In addition, they are resistant to rust, chemicals and high heat therefore making them applicable in many different environments without being damaged. Another great thing about stainless steel pipes is that they are extremely sanitary. As a result this makes them an ideal solution for those working in the food and medical industries, where hygiene is at paying copious of respects paramount with regards to avoiding contamination.

Stainless steel pipes may be very strong and last a long time, but they are not immune to damage or corrosion. One easy thing to do that will keep these panes in order is cleaning them regularly. For cleaning, you can wipe down with warm soapy water and a soft cloth. Its important to dry them well after you have cleaned the sunglasses, because If water spots make themselves at home – it can look very unsightly. One idea to save the septic are feeding harsh chemicals can result in damaging some of your lead pipes. The chemicals are very strong and in the end, they can ruin the stainless steel as well lowering its functionality.

When selecting stainless steel pipe for your project, one of the most important things to consider is how large and thick you need the pipe. The diameter indicates the size of a pipe, ie., it is a measure to determine how wide across in type and length. Its thickness is expressed as gauge. Keep in mind that the 31 P6 is a higher gauge number meaning thinner pipe so this will help with design.

Depending on the pressure and temperature which will pass above that pipeline you can decide what size and thickness of pipes are required. So, having this knowledge will enable you knowing what gauge to choose when the pipe is pressurised so it does not buckle or burst. Also, make sure to get the length of how far the pipe will be placed. This means you need to be sure the pipe diameter is correct and fits well into that space.

Clinet offers a 24- 24/7 online support after sales. If there are any problems related to the product, like for stain steel pipe, appearance or packaging, we'll be the first to fix them.

We have stain steel pipe cooperation with over 200 steel suppliers both in the United States and overseas, are able to supply carbon steel, alloy steel, stainless steel plate, tubes, coils, various types of profiles, and hardware accessories. We are committed to providing customers with the most suitable solutions to meet individual customer specifications.

As we've provided products and services to more than 80 countries and regions, our cross-border transportation is a rich experience and dependable. We have a stain steel pipe logistics team, sea air, land, and sea transportation is able to meet, the goal is to offer the fastest and most secure way to deliver the goods to you.

All our products can provide ISO, BV, stain steel pipe and other certifications. Control the entire production process for quality of the product to ensure the stain steel pipe quality of products, give test results, but also accept tests by third-party testing organizations. Our goal is to provide customers with top quality steel products.