Do you want a tube that is strong and reliable? Do you know about the SS seamless tubes? These tubes are a handy tool for jobs within and outside of fields! Allow me to share my thoughts on these pieces and why I think they are unique.

SS seamless tubes are the type of stainless steel. This special steel is super tough and can endure for a very long time! These tubes are designed to bear high pressure and loads without breaking. Which is why they are good for making tall buildings and strong bridges. It is also used in factories where actual product are manufactured. The tubes are also virtually resistant to rust so they will remain sturdy and usable for a long period of time.

SS Seamless tubes are widely used in different jobs of many industries. Ensure operations in the oil and gas industry by providing reliable transportation for liquids as well as gases. The food and drink industry also use them to transfer liquids (from water, silicone greases and fuel) and gases. Those tubes might even show up in medical machines, like MRI Machines!! There is likewise a fantastic selection of woods, and both aluminum and steel staging alternatives are available. Their strength in addition to their resistance against rust makes them one heck associated with an option for any kind of use.

SS seamless tubes Handles High Pressure Efficiently — One of the best characteristics of SS Seamless Tubes is that it has a capability to handle high pressure. So these containers can withstand the high heat of temperatures and changes in pressure without being ruined. As such, they are frequently employed in the conduits carrying both liquids and gases or to produce steam by using it in boilers. They are also used where fluids or gases need to be moved under great pressure such as in many machines. SS seamless tubes are an excellent option if you wish to safely transport liquids or gases.

Tushar, well then how are SS seamless tubes made? First off, they heat a piece of stainless steel and make it white hot. It is then rolled into a tube shape. Following this, when the tube has reached its appropriate size it is drawn through what are known as dies, which is a specialized tool. This process actually increases the strength of the tube!!! Seamless tubes literally do not have any weak points & they are solid and can withstand pretty much anything you throw their way — this is great for leakage. This design not only prevents liquids from spilling out but ensures that the inner surface of the tube remains smooth. This homogenization increases with the smoothness of flows, reducing any steps or turbulence.

There are many areas in which SS seamless tubes used. For instance, in the construction industry it is useful to construct powerful buildings and sky reaching bridges. Machines and tools manufacturing in factories we use by them as well. Also, tubes like these are found in cars to make motor components, which helps a car work! They are particularly strong, long-lasting and they can also resist the effect of rust; Indeed Steel tubes have a countless number application for various purposes.

ss seamless tube products come with SGS, BV CE and other certificates. We track every aspect of production quality, ensure that it is strictly controlled and provide testing results, however, we also allow testing from third parties. Provide assistance to customers in finding high-quality steel products.

Clinet offers a 24- hour online ss seamless tube support. If there are any problems regarding the product, for example, the appearance or packaging or appearance, we'll be the first to address these issues.

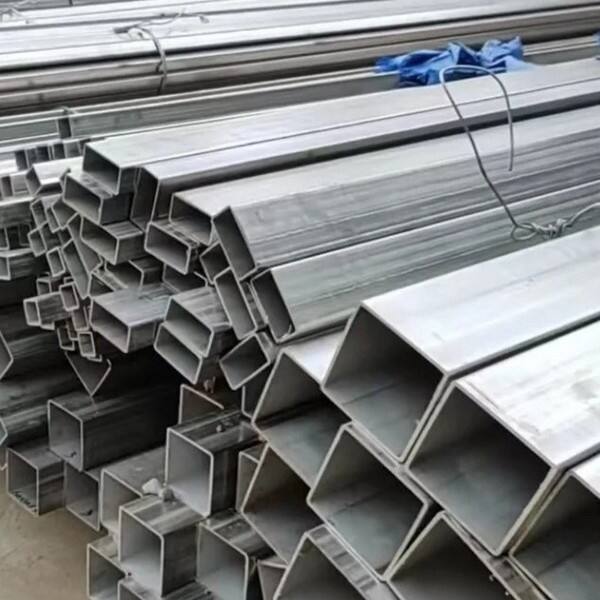

We have established a close connection with more than 200 ss seamless tube manufacturers throughout the country and internationally. We can supply carbon steel, alloyed steel stainless steel coils, tubes, all kinds of profiles, as well as hardware accessories.

We have plenty of expertise in transport ss seamless tube borders offering products and services to more than 80 countries. Our logistics team is reliable, and we offer sea, air and land transportation. Our goal is to ensure the most efficient, safest delivery.