Hot rolled steel sheet is a new type of metal material in construction and manufacturing. There are many uses of steels, e.g. steels being hard and tough in nature. We will know more about Hot rolled steel sheet production, its characteristics, properties and applications.

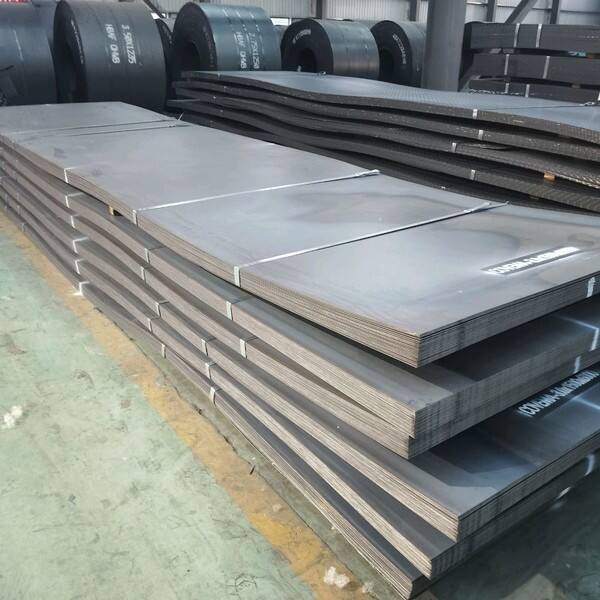

Hot Rolled Steel sheets are affordable, neat and clean process; it is a form of free steel from rusting. This process is known as hot rolling, and it names the steel sheet. The hot rolled steel sheet has to cool down, cut in the correct size afterwards used on different projects.

Strength: Probably the largest of all hot rolled steel sheet in construction, is its strength. It can resist enormous loads and external forces, making it perfect for building structures such as bridges, buildings or even some types of automakers. In addition, it is easy to recycle and cost-effective material because Hot rolled steel sheet, so for construction purposes Steel is a sustainable material.

Hot rolled steel sheet is used for a very wide gamut of manufacturing processes and encompasses tanks, metallic bars, metal amplification, etc. It is one of the more frequently utilized materials when manufacturing automobile parts, machinery or appliances and at the same time it is being used for some furniture. As a result, its versatility and longevity make it among the top choices of manufacturers who wish to deal with materials that they can entrust for quality.

Hot rolled steel sheet offers a tough, formable surface capable of being shaped in almost any manner without the downside of weakening its structural integrity. A non slip surface can occur on aluminum in one of two ways- Not only is it heat treated after making it to the desired shape, but there are also many textures available when rolling substrate. In addition to being low carbon, it requires those objective qualities and has extraordinary weldability, making the sheet simple to weld – only one reason why hot rolled steel sheet is so broadly utilized.

Hot rolling is the process of heating steel ingots to a temperature as high as 1200 degrees Celsius in order to generate steel sheets. The hot steel then goes through roller and is reduced to sheet. For this reason, the steel sheet obtains a uniform development of mechanical strength and resistance block, which are requested in industries using these plates.